Family business

My husband Rob is a great sport and support. He’s always encouraging me to follow my dreams, albeit in a responsible way. That included my decision to become a Baby Lock Sewing Machine dealer.

As I took on this new responsibility I asked him if he would accompany me to St. Louis, MO, the headquarters for Baby Lock. And, would he become my repair technician? He’s retiring in about five years so doing this part-time would be a good segue into retirement.

Technical training and product knowledge

Our trip to St. Louis would include a week of technical training for Rob and I’d be taking product knowledge classes.

Rob would needed to do some prep work before the trip, watch some training videos and learn how a sewing machine works. He is also supposed to get some basic training from me on threading machines bobbin winding, acceptable tension, etc. before we go.

Refresher sewing class

So we decided he’d make himself a shirt. After all, there’s nothing like hands on experience! Rob is not an absolute sewing novice. He grew up in a family of quilters and had taken a quilting class taught by me about 12 years ago where he pieced and hand quilted a reasonable sized wall hanging, doing a good job of it.

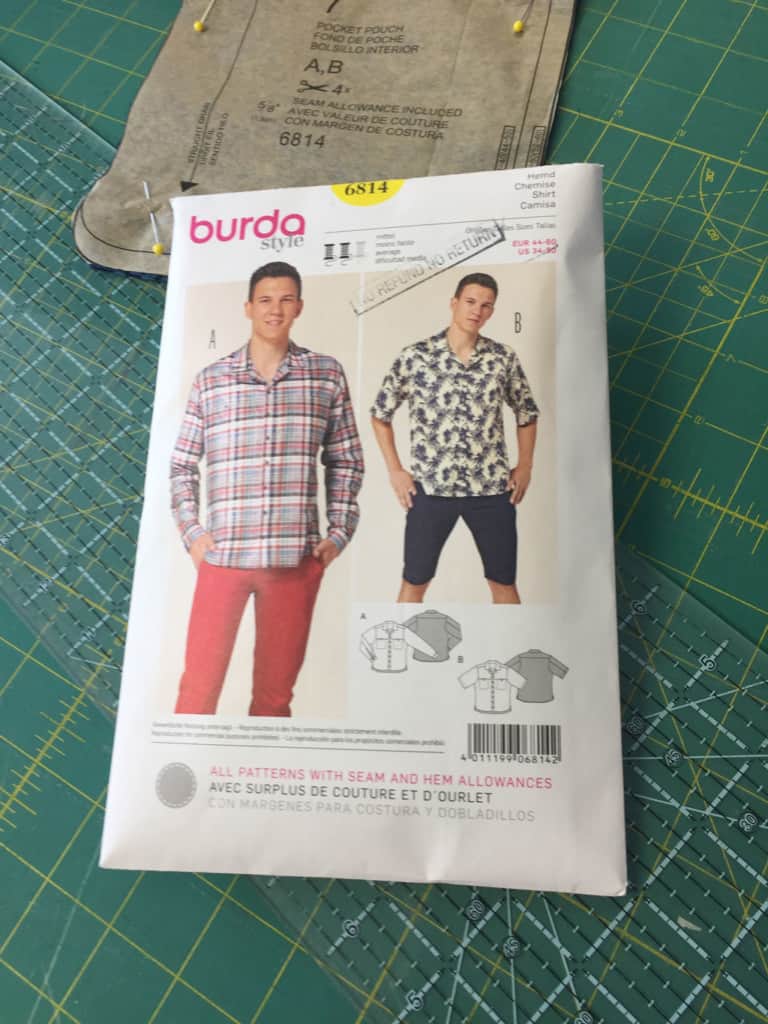

Saturday was designated ‘shirt making day’. I nipped over to the local Fabricland to pick up a Men’s shirt pattern the night before.

Read the pattern, pin, and cut

We rolled into the ABQ Sewing Studio nice and early. An early start was essential, as Rob would also have to learn how to read a pattern, pin and cut out the pattern pieces and mark the pattern.

That part went reasonably smoothly except for the part where Rob impaled his finger on a pin. Without any bandages handy (I must get some!) we masking taped his wound and continued.

Various stitches and buttonholes

Working on the Destiny sewing machine, Rob sewed almost perfect (my fault, not his) inset pockets. I got to do the un-stitching.

He used an overlock stitch to finish some raw edges and tried out several different feet for his pocket topstitching.

Threading, winding, tension, and feed-dogs

Between steps I showed him how to thread several different machines, wind bobbins, drop feed-dogs and we looked at some samples of good tension v.s. bad tension – a short course in understanding sewing machines.

The shirt is nowhere near done, but he’s clearly interested and he claims to have had some fun, notwithstanding the taped finger. I think the one-step buttonhole was his favourite part. And why not, it’s so easy!

We’ll get together again when he has a day off, to work on his shirt, and with luck, it’ll be done and ready to wear for our trip to St. Louis.

Hi Brenda and Rob… this a pretty monumental first go at the BIG Babylock, and you should both be so proud. Congrats, Rob on supporting Brenda’s dreams. And to Brenda – way to go!! Celebrate that you are working together so well and that Rob is really interested. I love the fabric choice and this will certainly impress the folks in St. Louis… have fun along the way! Explore – it is a beautiful city!

Bethany in Kingston, ON

(Great mentors would be Donna and Paul Taylor from Taylor’s Sewing Centre in Brockville – almost the same scenario some many years ago. Donna has retired and their shop was sold to one of their staff, but Paul is still at the store as the greatest, sought after Sewing Machine Tech. in Eastern Ontario!)

Hi Bethany, Yes it is monumental and Rob is a big part of moving ahead with this dream.

I have a funny habit of saying good morning to the machines every day like they are old friends already. Thanks for the tip, perhaps Rob will meet Paul some day in St. Louis! We’ll have to stop into the shop sometime on our way to Ottawa. Life is an adventure isn’t it?